Common issues (big and small) with JB74s

Now the JB74 has been out for a while, you start to see some trends in the various forums and FB groups about issues people have. Many of these issues are not large issues, and this is not an official source so don’t go citing this page to your dealers! I will generally try to source various things I’ve seen on this e.g. forum posts or FB group posts. Potentially some of these groups are private so I will also include a screenshot which might help to find the info if the group becomes defunct or archived.

I have now compiled a list of 5 door common issues; that list is to be read in conjunction with this list as basically all of the 3 door issues flow over to the 5 door, but it adds a few extra differences of its own.

Sections

- Recalls

- Operational issues that maybe aren’t issues

- Mechanical issues

- Transfer case noise

- Reluctance to shift gears in auto after 4wding

- Alternators and/or idler pulleys

- Wheel bearings (especially rear)

- ‘Excessive’ brake wear

- Phantom traction control, esp. after a lift

- Steering pulls right/left after a lift

- Rear tailshaft CV joint boot splitting/tearing

- Crank and/or cam seal and/or sump sealant leaking

- Autonomous braking camera malfunction

- Manual transmission issues

- Rev hang/random revving/throttle surging/limp home mode

- Cosmetic and interior issues

Official recalls: Australia

To monitor recalls, I’d suggest searching the official Australian vehicle recalls website for Jimny. I will try to update this page when I hear of other recalls but to date, only 1 has been required on a large collection of the cars sold.

Door wiring harness (2018-mid 2020 cars)

This is the most extensive recall to apply to gen4 Jimnys in Australia. Recalls numbers REC-001620 (Suzuki Australia, 2806 cars) and REC-001624 (Suzuki Queensland, 1231 cars). This recall is for door harness wiring that might break from repeated opening and closing of the door. The risk with this is that the side impact airbag sensor might fail to operate in an accident. The fix is replacing the wiring harness.

My car was one of the affected, and I had it done at a routine service – I notified the dealership, the service was coming up soon, so they made sure they had the parts ready and sorted it at the same time.

Fuel pump hose swelling (some 2018 cars)

Recalls numbers REC-001621 (Suzuki Australia, 166 cars) and REC-001625 (Suzuki Queensland, 40 cars). This recall relates to an incorrect part in a fuel pump (I think a hose) that might swell with certain conditions, meaning the fuel pump might stop working which would stop the engine running.

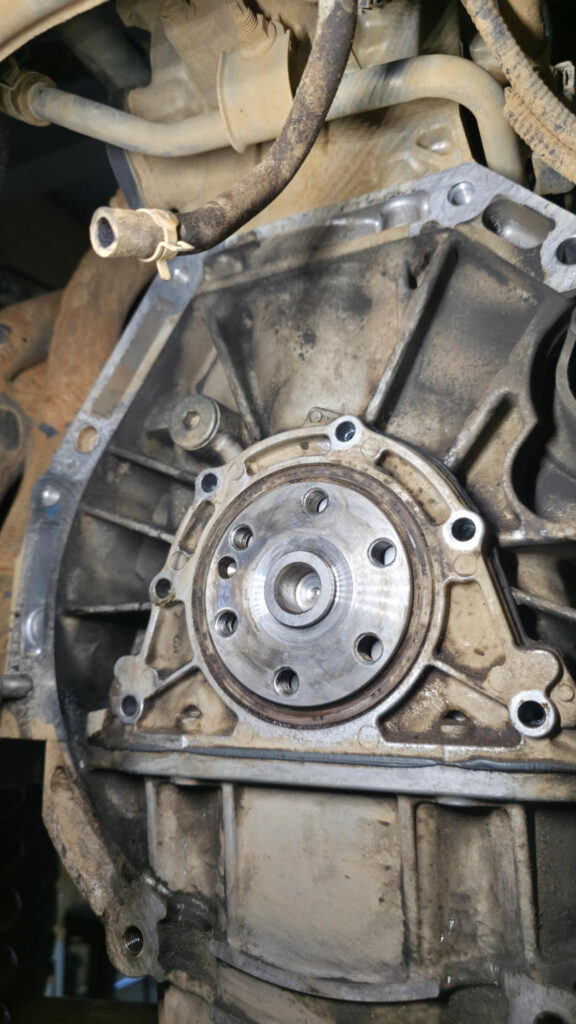

Auto transmission seal (some 2018 cars)

Recalls numbers REC-004954 (Suzuki Australia, 21 cars) and REC-004953 (Suzuki Queensland, 6 cars). This recall relates to an automatic transmission seal on these cars meaning they might leak transmission fluid and, in the worst case, lose drive as a result.

Windscreen and rear window bonding (some 2020 cars)

Recalls numbers REC-001611 (Suzuki Australia, 12 cars) and REC-005377 (Suzuki Queensland, 4 cars). This recall is for windscreens and rear windows that may have been incorrectly bonded to the car and thus might loosen and leak or come out during use of the car.

Fuel pumps (All MY2019 cars)

Recalls REC-005929 (announced March 21, 2024; Suzuki Queensland) and REC-005927 (announced March 25, 2024; Suzuki Australia) apply to MY2019 cars. This recall relates to material used to manufacturer the fuel pump impeller. This impeller may swell over time, stopping the pump working. What’s interesting is this was reported in Europe/UK in 2021 and subject to a recall there; it might be something relating to the average petrol composition in each market that it took longer to become apparent in Australia.

Some people have reported requiring to pay labour involved in removal and refitting aftermarket fuel tanks like the 80L Long Ranger replacement tank. Other dealerships have been prepared to do the recall even with an aftermarket tank that takes more time to remove and not charge the customer, so it is worth a conversation with your dealership to understand if you’ll have to pay or not. On one hand it isn’t the aftermarket tank’s fault that the stock fuel pump has an issue, however, it does take more time and complexity to remove adding time to the recall procedure.

Issues with the operation of the car people complain about

Speedo errors

The rise of infotainment systems and ubiquity of using navigation via GPS or through a phone means people are more acutely aware that speedometers don’t give exact readings. Typically an error of overreading 4-6 km/h at 100 km/h is what people see with the 4th generation Jimnys i.e. the speedo will say 104 to 106 km/h when a GPS speed reading of 100 km/h is observed.

This is normal in the sense that all car speedometers (at least in Australia) will only ever overread and they build in some tolerance to ensure there’s some headroom in case of tyre variation. (Tyres can vary 4% from nominal sizes for offroad focussed tyres, so even sticking to a ‘stock’ size could result in that magnitude of error).

In Australia, since 2006, speedos are required to:

- Never underread the actual speed

- Overread by no more than of 10% of actual speed + 4 km/h

This means the car can display up to 114 km/h at 100 km/h actual and still be within the ADRs.

There is a benefit to this inaccuracy: if you fit the largest legal tyre size of a 29″ diameter tyre, the diameter change of 5.6% will put the speedo very much correctly accurate. This does depend on how closely the tyre follows the nominal sizing but most seem to. No need to adjust anything or fool the speedo if you’re keeping it all legal.

As a bonus: most cars with digital speed to the gauge cluster will add the tolerance only to the speed. If you verify distance travelled over time using the odometer you will find that it is accurate. This is because no car manufacturer wants you to think the fuel economy is worse by 4 or even 10% which is what would happen if the odometer was also fudged. You can verify that the odometer is accurate by driving on a nice flat road for a time at a constant speed based on a GPS reading and you’ll see your average speed & distance travelled given a particular time makes sense based on the GPS speed but not the speedo. An example would be sitting on 100 km/h on the speedo for 30 minutes: if you reset the odometer at the start while at speed you’ll see you’ll travel 50 km in that 30 minutes, but the speedo will be sitting on ~105 km/h; if that speed was correct you should have travelled 52.5 km in the same time.

If you want to verify the speedo accuracy there are a few options:

- GPS on a flat road

Use something that displays GPS speed e.g. phone navigation software like Waze or a handheld GPS unit. People worry that GPS is inaccurate (which it is, to a known amount) but for measuring speed you only need the relative distance between two points. Assuming a reasonable view of the sky and a flat road then the precision of GPS between position acquisition is sufficient for accurate speed measurements. Even a crap portable GPS using a near 20 year old phone gets race times on a race track to within 100ths of a second, and that relies on more position accuracy than a speed measurement does.

GPS speeds can be less accurate up a hill as GPS heights are less accurate and their precision is worse than horizontal positions. Verifying speedo accuracy is best done on a flat road for this reason. - Go a set distance at a particular speed on cruise control and time it

Do not rely on the odometer for this set distance, as noted it is more accurate than the speedo (true of almost all cars, in fact) - Use an OBD2 reader to check vehicle speed sensor signal

The Vss signal is usually more correct than what the speedo displays so it can be another good way to see what speed the car thinks it is doing. Many OBD2 readers can access this through the diagnostic port; the Bosch 7″ infotainment unit also can read it if you put the unit into diagnostics mode (hold home and settings button for 10 seconds with car stationary; then you can drive and see what speed the car actually thinks it is doing). - Use an OBD2 reader to obtain the engine RPM and verify speed against gearing

You can also use an OBD2 reader to get an accurate gauge of engine RPM. Driving at a constant speed on cruise control on a flat road, check the engine RPM and the displayed speed on the speedo. When you get home, you can use the gearing of the car to work out what speed that RPM would equate to.

If you really want to get this accurate then you need to measure your loaded tyre diameter: mark the tyre, push the car along for a couple of rotations of the tyre and measure how long the car travelled for those rotations.

This can be super useful if you have fitted larger tyres, although you have to make sure to account for those larger tyres in the calculation of vehicle speed given RPM. It is a little trickier with automatics as you need the torque converter to be locked up for it fully to be accurate.

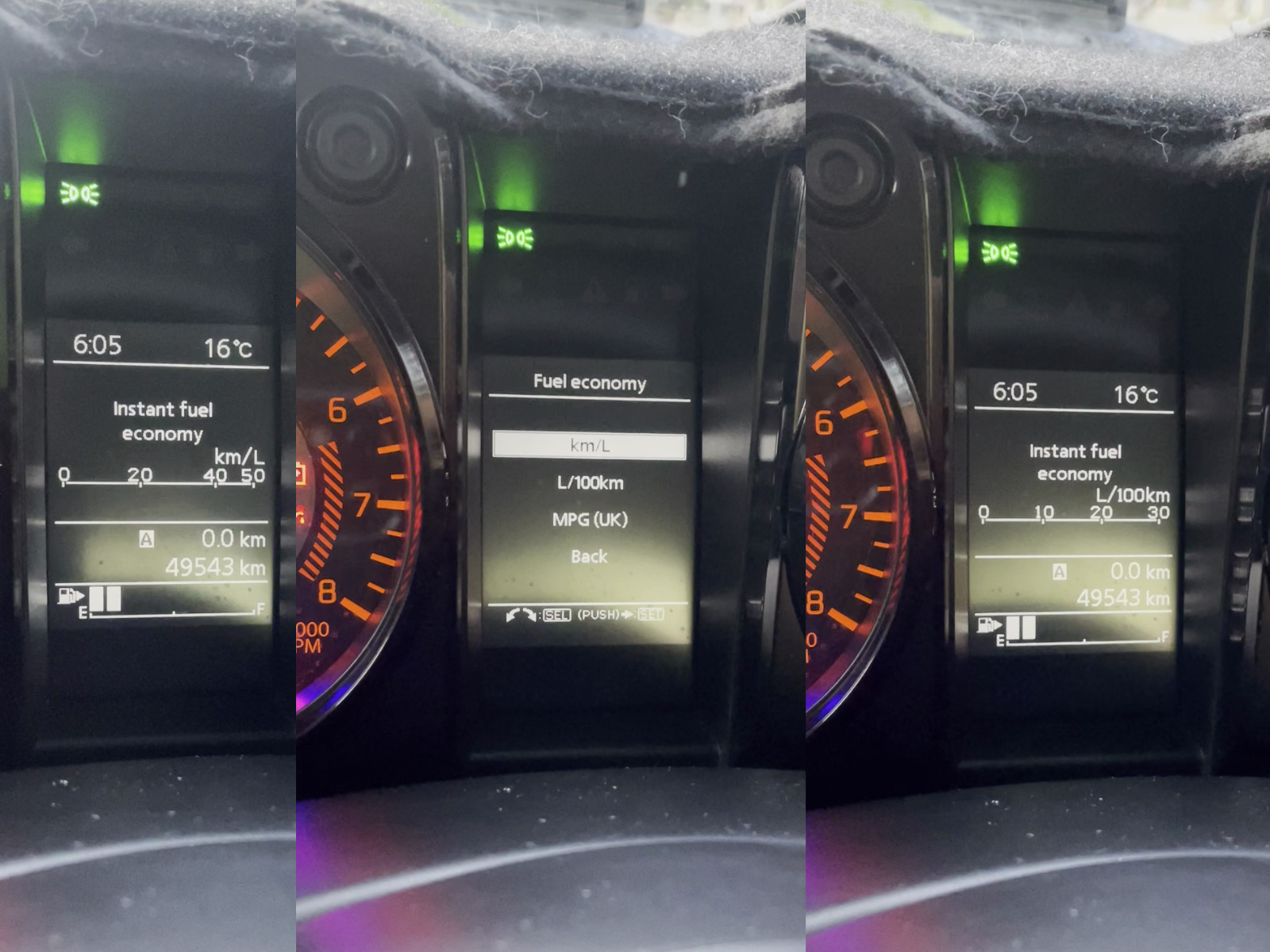

“Why is my fuel economy so bad” / default fuel economy display in km/L not L/100km

Many people seem surprised at the not-great fuel economy for the Jimny. A fair amount of these people haven’t realised that the default fuel economy is displayed in km/L not in L/100km that they might be more used to in Australia.

You can change this quite easily. With the vehicle stopped press and hold the button on the right of the instrument cluster. After a few seconds this will bring up the settings menu. Navigate this menu using the same button by turning it left or right, and to select something press the button in and release it. You’ll be able to get to the fuel economy setting, adjust it to L/100 km (or even MPG if you want) and then navigate through the menu to leave the menu.

That said, fuel economy of a Jimny varies a lot. If you have a stock one, especially a manual, and you drive it sensibly then you will get the reported economy or thereabouts. Once you start modifying it: adding weight, roof racks, larger and heavier tyres you will find the economy suffers. The economy also suffers through the brick-like aerodynamics of the car, especially at highway speeds. The sweet spot is slower than you think. It isn’t bad economy for a 4wd, but it isn’t great economy for a small 4 cylinder car compared to modern hatchbacks. If you bear in mind that the things that make it good offroad make it less ideal for good fuel economy then those reset expectations will help.

On average, they are a little better than a generation 3 Jimny and, if you go through the history I’ve pulled together, they actually are much better than the 500 and 800cc LJ Jimnys, and even better than the much less powerful 1L and 1.3L Sierras!

Automatic window winding does not work

This is something that comes up after someone has had the battery disconnected in their car. The driver’s window is the only window from the factory which has an automatic winding function, however, the start and stop position needs to be relearned after you disconnect the vehicle’s battery. To do this, you first press the window switch and hold it till the window goes down and keep holding it for 2 seconds after it is fully down. Now use the switch to raise the window, holding the switch until the window stops and keep holding it for 2 seconds. The window up and down positions will now have been learned and automatic winding will be restored.

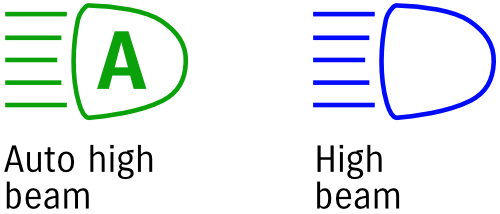

“I can’t get high beam to work”

This is quite common with people who have a Jimny with the automatic headlights, not realising that the automatic mode on the headlight isn’t just auto on for the headlights, but also auto high beam. If you push the headlight lever forwards with the headlights in auto mode, a green headlamp symbol with an A in it will appear. High beam will only activate if the car determines there is not an oncoming car and you are going at a moderate speed. Putting the headlights into on mode with the rotary selector at the end of the stalk will provide manual high beam control.

Related to this: if you wire up driving lights correctly with a trigger off the high beam signal they will correctly turn on and off with high beam as well in automatic mode.

I use the automatic high beam a lot and it’s proven to be very effective and reliable for me. If you incorrectly adjust your driving lights you can fool it with reflections off road signs, but otherwise it works fine if you correctly adjust your headlights too.

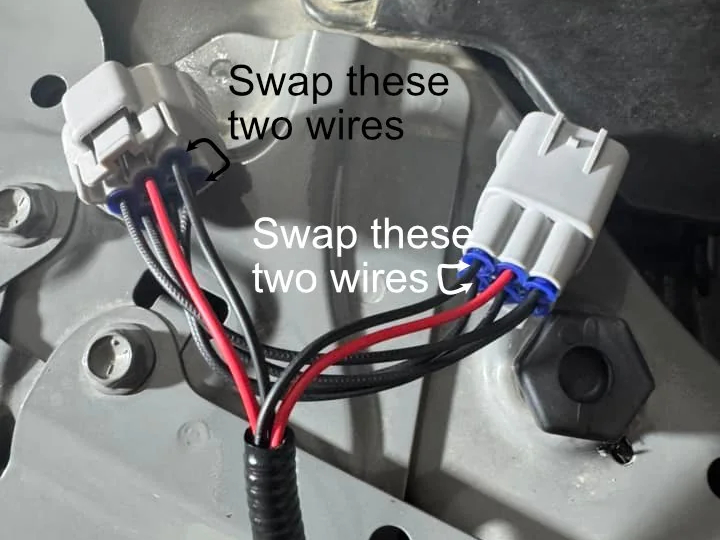

My driving lights don’t work when it’s on high beam

This is another classic one. Assuming you actually have the headlights in ON rather than auto, i.e. you’re actually getting high beam to trigger rather than relying on the car triggering it for you, usually this is down to incorrect wiring of the headlight piggyback harness you’ve used. Most harnesses are wired incorrectly. I think this is a part QA/QC factor: the harnesses are likely manufactured by the thousands offshore, and they are the same connector as an Isuzu D-Max (and probably other cars). The high beam signal is in the same spot as the D-Max but the earths for the headlights are not. The -ve side of the headlights are used as the earth for the switching side of the driving light relay in a lot of commercial wiring harnesses. This means the relay never switches and so your driving lights never get power.

The switch is simple: you can repin the piggyback harness to put the -ve signal in the right spot, or you can rewire the driving light harness to independently earth the switching side. Usually repinning the connector is the easier option though I would argue that it’s not hard to separately earth the relay either, but it’s harder for me to provide generic instructions to do this.

This is an example from helping someone on a Facebook group get their driving lights working.

In essence, if you think of the connectors as two ‘rows’ of 3 pins, have the red wire out to the driving light relay at the ‘top’ and the black wire out to the relay wiring will need to be on the other row for it. Usually companies wire it with it at the top, which is correct for an Isuzu D-Max (same connector) but not a Jimny. If you swap the top and bottom pins in that column of pins then it’ll work as earth is now in the right spot.

Sometimes with these things you need to do a bit of wiring tracing to make sure that 4 pins are being passed correctly to their corresponding pins, and what needs to change. You need to also think through the fact that the pins are mirrored when they’re plugged into their other gendered plug so some care/thought is needed. This is an example from Reddit of tracing the wiring and checking it against the pinout for the connectors; even with the left hand connector turned around a bit it’s still possible to see that the black wire is in the wrong spot.

Even in this example, pins 1 and 4 are in the wrong spot for the black wire going out to the relay wiring to be an earth, so swapping them will make the earth be in the correct spot and likely the driving light relay will work.

I have provided instructions on how to repin these connectors which should fix your issue. If it doesn’t then you’re in the 0.1% for whom there is something else going on, sorry!

Traction control not disabling in 4wd

This one isn’t an issue per se but it comes up a lot. If you exceed 30 km/h in high range, either 2wd or 4wd, traction control will enable itself even if you have disabled it using the switch. This is not unique to the Jimny: many other 4wds do this now and it comes back to safety standards. 4L disables traction control completely except for brake LSD/allgrip functionality which is useful. (If you hear traction control working via the ABS pump activating when you are offroad in low range then that’s a sign one wheel lost traction and the car is helping you out. It’s not a bad thing!)

You really have 3 options here:

- Use 4L and potentially skip shift gears in a manual

- Put the car in ESP service mode

- Yank the ABS fuse to disable it

I’ve listed those in my *personal* preference of control measures. In an auto it can be good to use low range because it reduces the torque converter slipping and heating up the fluid in high load situations; in a manual it just means you might need to take off in 2nd gear rather than first if you don’t want super short gearing everywhere. Putting the car in low range is obviously pretty straightforwards, although it can require a bit of force on the transfer case lever – especially when the car is new.

Note that if you use low range you will still periodically get the ABS pump activating and traction control light flashing up. That is the product of the ‘brake traction control’ activating because you have lost traction on one wheel, and it’s clamping the brake on that wheel to send power to the other wheel on that axle. That’s a good and useful thing, and can really help you out in a situation where you’d otherwise need a locked differential.

ESP service/maintenance mode is probably the next best option to low range. There is a connector above the accelerator pedal which, if you bridge the two contacts, will let you put the car into service mode to disable the traction control system. This has some benefits of retaining other useful functions, and, unlike the ABS fuse option, it will mean the ESP system won’t get confused if it thinks the car is swaying but it cannot control it because it can’t apply the brakes. It does not retain any codes relating to being put in service mode so it’s also, assuming the jumper wire is removed, not something that can be detected per se.

Putting the car in service mode is covered by this no nonsense video:

The final option is to yank the ABS fuse so the pump cannot activate the brakes for traction control. The car, however, can choose to ease the e-throttle and/or reduce timing and fuel injection demand if it wants to. The car may also wish to do other things under the ESP system as mentioned above, and if it can’t see how to do that with the brakes due to the fuse being pulled then it might choose to go into a limp mode. It will also leave some codes stored in various modules each time you start the car, although generally won’t leave persistent warning lights. Hill descent will also be disabled doing this. You also won’t have ABS – some would argue that’s a benefit, but it depends on the offroad situation especially with modern ABS.

You can also buy very expensive modules that basically lie via canbus to the ESP system about what speed you’re doing, while reporting the right things to the transmission control module for autos and the dashboard. These are quite expensive so I haven’t explored looking at them.

There is a reason that you’ll want to look into disengaging traction control offroad: your clutch, if you have a manual. If the traction control is going bananas stopping most of the wheels and you’re revving the car a lot then the thing that deals with that speed difference between what the engine is doing and what the ESP will let the wheels do is the clutch. The Jimny has a small, light clutch befitting its small, lightweight nature. This, however, means that the clutch is not ideal for coping with this stress and you can find yourself very quickly ruining the clutch. This is also why you should let your tyres down offroad too – get yourself some more traction so things are less likely to go bananas and weird and you’ll do less damage to the car.

“What’s that noise” offroad

This one is 99.999% related to the above: traction control! Offroad the sound of the ABS pump activating can be pretty alarming, it sounds like quite a harsh rubbing or scrubbing sound. People often mistake it for tyre rubbing. Look for the flashing ESP light in the instrument cluster. This will flash even if it is just brake LSD activating, so you can see what is happening.

Obviously if you’ve fitted larger tyres as mentioned you might also have a light bit of tyre scrubbing. Even with a suspension lift you don’t necessarily increase clearance between the tyres and the body at full suspension compression, so, you might actually have found the point at which your tyres scrub. Common areas is the inner wheel well at the front where the guard liner meets the front bumper; also the upper rear arches at the back can get a little rubbing in some situations too.

Not engaging low range

The move back to a mechanical transfer case shifting mechanism has brought with it some challenges, especially the 1980s action film levels of force required sometimes to shift the car into low range. Some people have also reported issues with it repeatedly not staying in low range, however.

In terms of shifting, you have to push down on the lever and it requires quite a firm shove backwards to make sure it’s fully engaged. It can feel engaged but not quite be there and then a few hundred m down the road it’ll pop out of low range. Much rarer but you can find a little spot where it won’t engage either high or low range, too, although the transfer case doesn’t have a specific neutral position between high and low range.

One other thing to check with this issue is anything that might be restricting the transfer lever moving far enough backwards. The cupholders that go around the transfer lever can be guilty of this: I fitted one to my car and I went from not having an issue to not getting low range to correctly engage. Moving it backwards so it gave a bit more room to the boot for the transfer lever helped, or just remove it entirely offroad. They’re not really strong enough to hold a drink offroad anyway!

If all else fails and you are absolutely sure you are putting it firmly back into low range with the lever pressed down then chat to your dealership. Often times it is the reluctance to register a fault that hinders future warranty stuff: an issue you’ve kinda lived with from day 1 is to a dealership nothing until they know about it. Establishing a pattern helps demonstrate a fault.

Mechanical issues

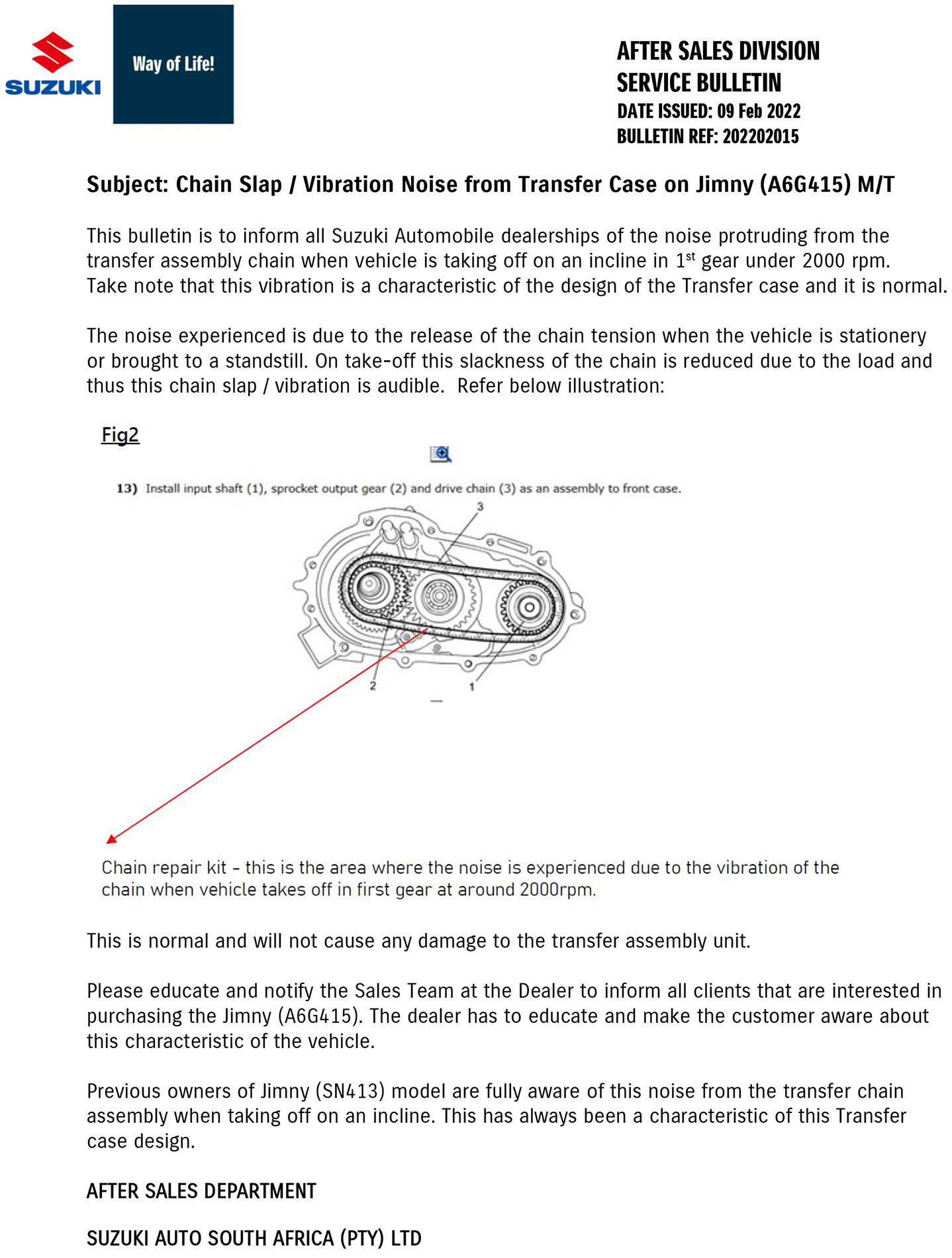

Transfer case noise

This only seems to affect manuals, and it’s most apparent when taking off in first gear with a bit of load on the car. It manifests itself as a vibration/graunch sort of noise, usually on takeoff or at around 2000 rpm if you’re adding throttle. Very rarely but there are non-zero numbers of people with automatics who see a similar thing. Automatics, by virtue of a torque converter, have more ability to ease load into components so this might be why there’s a difference. A thread on auszookers discussing the topic definitely demonstrates some automatics can do it.

This issue has been discussed extensively on many forums and in FB groups.

Early on, some of these issues were dealt with via a warranty claim. This warranty fix involved removing the transfer case from the vehicle, and replacing the drive chain within it. There are at least two revisions of this chain, at least anecdotally, but most people who have had the noise come back.

In my experience, you can influence the noise with quite subtle changes to how you take up drive in the car. I can drive my car and make no noise, and someone else who is driving it and seemingly doing the same thing will make the noise. It can be worth experimenting with taking off with more slow clutch slip and less initial throttle input till you exceed 2000 rpm, just to see if you can find a sweet spot to not make the noise.

Although I do not have access to service bulletins, Q-A6G-004 was the original bulletin discussing this and the fix, and there is apparently a revised one for some markets (Q-A6G-008) which basically states “this is a characteristic of the model, the Sierra transfers were the same, reset customer expectations”.

Q-A6G-008 is discussed in a thread on bigjimny, as is the original bulletin. The deepest dive in Australia on the transfer case noise is inside a JB74 Facebook group which is private, but there is a thread with nearly 500 comments discussing it from 2019.

My current advice on this issue, as of the start of 2023, is to leave it alone unless you are seeing metal in the transfer case oils and the like. Ultimately the noise comes back for most people and any time someone gets inside some mechanical part there is always the risk of something else arising so might as well leave it alone.

Reluctance to shift gears in an auto after heavy 4wding

I’ve seen enough people talk about this that I’ll count it as an issue. This seems to come out either through the transmission fluid getting hot, or contamination of the transmission fluid meaning the solenoid involved in shifting a gear doesn’t want to work.

Most dealerships will diagnosis this as a transmission failure requiring a new transmission, as they are not equipped for a rebuild of the transmission and that’s one of the fault finding steps.

A transmission shop can, in the worst case, dismantle the valve body off the car and and then clean and/or replace solenoid(s) if this is the issue. All cases I have seen, however, have been fixed with a fluid change at this stage.

This would be a good argument for extending the automatic transmission breather but it is a bit of a pain to get to and not a super strong fitting into the transmission. If you are going to do lots and lots of hectic muddy and wet offroad segments and you are concerned about this, you probably want to lower the transmission slightly & see about putting a better fitting into the case for a stronger breather.

Alternators and/or idler pulleys after mud/water driving

Another common point of failure associated with mud driving or deep water crossing. The alternator is quite low on the engine in the Jimny (and it’s not the only 4wd guilty of placing it there) and so it is susceptible to mud ingress. Engine splash guards exist but you’re probably better off making one out of something like a politician’s corflute advertising sign instead of buying one.

Symptoms here include:

- Car not charging

- Noise from the front of the engine at idle

- Loss of engine accessory belt

It might be diagnosed by some mechanics as a water pump failure, but so far all cases that were initially called that ended up being either idler pulley bearing or the alternator itself. The alternator turns faster than the idler pulley so potentially the frequency of the sound and how that relates to engine revs might give you a clue as to what it is.

I have stripped down a Jimny alternator to help you understand what’s involved in the failures and also how you might rebuild one. If you require a full replacement, especially if you’ve trashed an alternator bearing on the shaft rather than the bearing in the case, then a good option is a K12C alternator from an Ignis from about 2015 onwards. This has the same part number as the JB74 alternator (31400-81P00) and is a direct fit. It’s also a lot cheaper from a wrecking yard instead of buying a new one from a dealer.

Wheel bearings (especially rear)

People have been reporting wheel bearing noises or failures, especially in 2020 onwards cars. It is more correlated with heavy 4wd use, especially mud or water crossings, but also larger/heavier tyres with more offset. Not uncommon in many 4wds, not just Jimnys, for wheel bearings to struggle. Jimnys in particular will be susceptible to this as you can quite easy get some big wheel lofts meaning you’re nearly-at-GVM Jimny suddenly has all of that weight on 1 wheel temporarily, usually at the back.

That said, it appears to be more common than gen3 Jimnys. Unsure if that’s just around expectations (more JB74 owners will complain about it) or something relating to the revised axles in the JB74. The bearing part numbers are slightly different but gen3 bearings appear to crossfit with gen4 bearings.

Although not at the point of failure (yet), my bearings are showing at the limit of acceptable play at ~60,000 km and 4 years so I will write up a bearing DIY guide when bearings come in and I get around to doing it.

‘Excessive’ brake wear

I mention this in the brake repair section of this site, but JB74s seem to wear their brake pads more excessively. Once again this is correlated with people who do heavy 4wding and/or mud work. The more aggressive programming of the brake LSD stuff definitely will play a part in this, plus the fact the car is heavier and faster than previous generations. The brake pads are revised compared to the 3rd generation pads, they are 1mm thicker per side, but otherwise many things are similar.

It is worth making sure your brakes are nice and clean after a big muddy session, too. Mud sticking the caliper on a bit will massively amplify wear, and often rear drums are neglected but they, too, full of mud will wear quickly.

“Phantom” traction control esp. after a suspension lift

This is something I’ve experienced a couple of times and I think I have an explanation, but like with many electronic control systems it can be a little tricky to get to the bottom of it.

Some people report the stability control responding weirdly. More commonly after a lift, and at least in Australia most people seem to talk about it happening on left-hand turns, this seems to be where the stability control is intervening as it thinks something weird has gone on, usually by braking a little on the outside wheels.

In both situations where I managed to get my car to do this it was brought about with a mid-corner lift on the throttle, unsettling the car marginally. I think this unsettling confused the G-sensor in the car which then misinterprets what’s happening in terms of steering and the ‘movement’ it’s expecting – the car basically is steering more without extra steering input, which looks to the computer like oversteer (and, in fact, it isn’t wrong per se – it just isn’t at a point where it is a problem). The car then brakes the outside front wheel a bit more, which ends up overloading it & inducing a bit of understeer. There’s also some bump steer in any live axle 4wd – indeed the geometry is never going to be consistent throughout the travel with a 3 link suspension arrangement – so then it all ends up fighting itself and intervenes a bit more and a bit more, untill the car gets itself more stable by going a bit slower.

It could be exacerbated by doing something weird around the steering angle sensor by doing something like changing the steering wheel position on the shaft instead of adjusting the drag link. In that case the car might think you’re going straight ahead

That’s my working hypothesis, though. Some people mention it without a lift but it could well be a combination of the car being a bit unsettled and the kinds of suspension changes in certain circumstances that could work against itself.

It was much more commonly mentioned for early cars; now with over 12 thousand cars in Australia it’s really not mentioned much. It might be something where the calibration of the ESP has been tweaked over time, dialling it out.

“Steering pulling after a suspension lift”

This is going to open up a can of worms especially with those who think what I’m about to say is wrong.

I think this one comes about through a misunderstanding of how intelligent the electronics are in the Jimny, and also wheel alignment places not necessarily doing the right thing. Fundamentally the Jimny has about the simplest wheel alignment you can do:

- there’s only 1 thing you actively adjust (the tie rods, adjusting toe in/out)

- there’s one thing you can adjust (the length of the drag link); and,

- you vary the caster with either offset bushes or replacement radius arms.

You can also vary the position of the axles under the chassis via adjustable panhards but that’s not really wheel alignment per se.

Unfortunately, there’s a few ways you can get the car confused. When you fit a suspension lift to the car, the body chassis lifts away from the axles and steering. This means the steering arm needs to be lengthened – this is the drag link. If you don’t do this the wheel will be turned to the side slightly (clockwise for a right-hand drive car at least). This is not ‘pulling’, the car with the steering wheel in that relaxed position will be driving straight. It’s just a bit weird cause the wheel is not pointing straight ahead. Sometimes people will just pull a steering wheel off and reset it so it now is straight. This is not the way to correct this – now the car’s steering angle sensor will think ‘straight ahead’ is not straight ahead and you might have issues

There is the added thing that once you lift the car, you change the self centering of the wheels by reducing the caster. This means the car will tend to ‘stick’ to a steering position, making you think your car is pulling one way. You can test this by then pulling the wheel a bit in the opposite direction and then slightly returning the wheel straight – it will now follow this new direction. A wheel alignment issue would *always* go to the same position.

What some people report after a lift is the wheel is actively pushing itself to a centre position which is off-centre and they do elaborate things to reset the steering angle sensor to make it push the wheel to where it needs to be. I’m not actually sure this is necessary unless people have done something to screw this up. There’s a few things to understand about the steering angle sensor which requires a bit of a deep dive:

1. The steering angle sensor position is self-learning

Although there is a calibration method for the steering angle sensor, this calibration method is only about initialising it. The steering angle itself is self learning in terms of what ‘straight ahead’ is.

Friction in steering system affects return feeling of the steering wheel especially at low speed of the vehicle. The compensation current based on “steering angle signal” transmitted from steering angle sensor is applied to assist the motor rotation in steering return direction and improves return feeling of the steering wheel. Neutral position of steering wheel is learned and memorized in P/S control module. Steering return control is used memorized neutral position. Steering return control is performed at each steering wheel position, so that return direction of steering wheel is assisted ideally.

Suzuki A6G415 Service Manual, section 6C – Power Assisted Steering System

I drove around for a couple of thousand km before I could be bothered getting a couple of spanners out to adjust the drag link and the car did not complain at all or push the steering around, even though it would have known the wheel was no longer straight ahead based on what it knew.

You could potentially get this wrong – if you have the ignition on and you rotate the rear wheels with the steering turned, the steering angle sensor could conceivably re-learn an incorrect setting. Again, turning to the workshop manual

NOTE:If only the rear wheels are rotated with the front wheels steered (with the steering wheel turned), a discrepancy between vehicle steering straight forward direction and steering neutral position learned by P/S control module may occur, resulting in an unexpected behavior of the steering wheel.

Suzuki A6G415 Service Manual, section 6C – Power Assisted Steering System

When rotating only the rear wheels on a tester, be sure to maintain the front wheels at straight forward direction (with steering wheel at neutral position).

This might happen if you put a car on a wheel alignment machine and rotate the rear wheels to take into account any bent wheels when setting the car up. If you did this with the drag link not adjusted but the steering wheel just pointing straight ahead, and the ignition was on then you would learn an incorrect steering angle position.

2. The steering angle sensor is not used precisely

Although the steering angle sensor has a resolution of ± 1º, the steering angle sensor precision required in the specifications is ± 10º because the steering system itself has some play in it fundamental to the type of steering box in a Jimny. Most suspension lifts (60mm or less) do not actually rotate the wheel more than 10º off centre, so it probably does not even come into play in terms of what the car relies on for the steering angle sensor.

3. The steering assistance that ‘forces’ a wheel back to centre only applies at low speeds

This function is called “steering return control” and is covered by the workshop manual in the quote I provided above.

The workshop manual does not define low speeds in this context, but in my own testing it really does seem to be in the 30-35 km/h range. Which makes sense, they’re the change points around the ESP system and stuff. At higher speeds the steering assistance from the electronic power steering is not based on steering angle but instead it is based on torque sensing only. If you want to see if it is the steering return control then you can disable the steering assistance by pulling the power steering fuse.

In short, I think if you have got to a situation where the steering angle sensor is doing some weird things then yes, you might need to follow procedures to reset it and reset it at an angle that makes the car work. However, I think if you install a lift correctly or don’t screw with too many things then it won’t be a problem. It is something that some people are very insistent is needed, yet out of the thousands of lifts installed that are mentioned in the Jimny groups, maybe a 50 or 100 people talk about their steering pulling after a lift. Generally people are vocal about a problem, though, which amplifies it.

Rarely have I seen someone talk about this as an issue when they have installed the suspension lift themselves. It does seem to come about when people have got wheel alignments and it is unclear exactly what procedures were done or not done to the car to make the wheel alignment right. Very few people seem to understand that the drag link is the fundamental thing to adjust to get the steering wheel pointing straight. A lot of people seem to play with the toe to get it right – but this does not change when you lift the car, and, unless you adjust both sides equally then you can end up with some weird steering geometry which will make the car steer differently left and right. Because the toe is linked between wheels via the steering bar linking left to right hand wheels then just adjusting one will affect the other wheel.

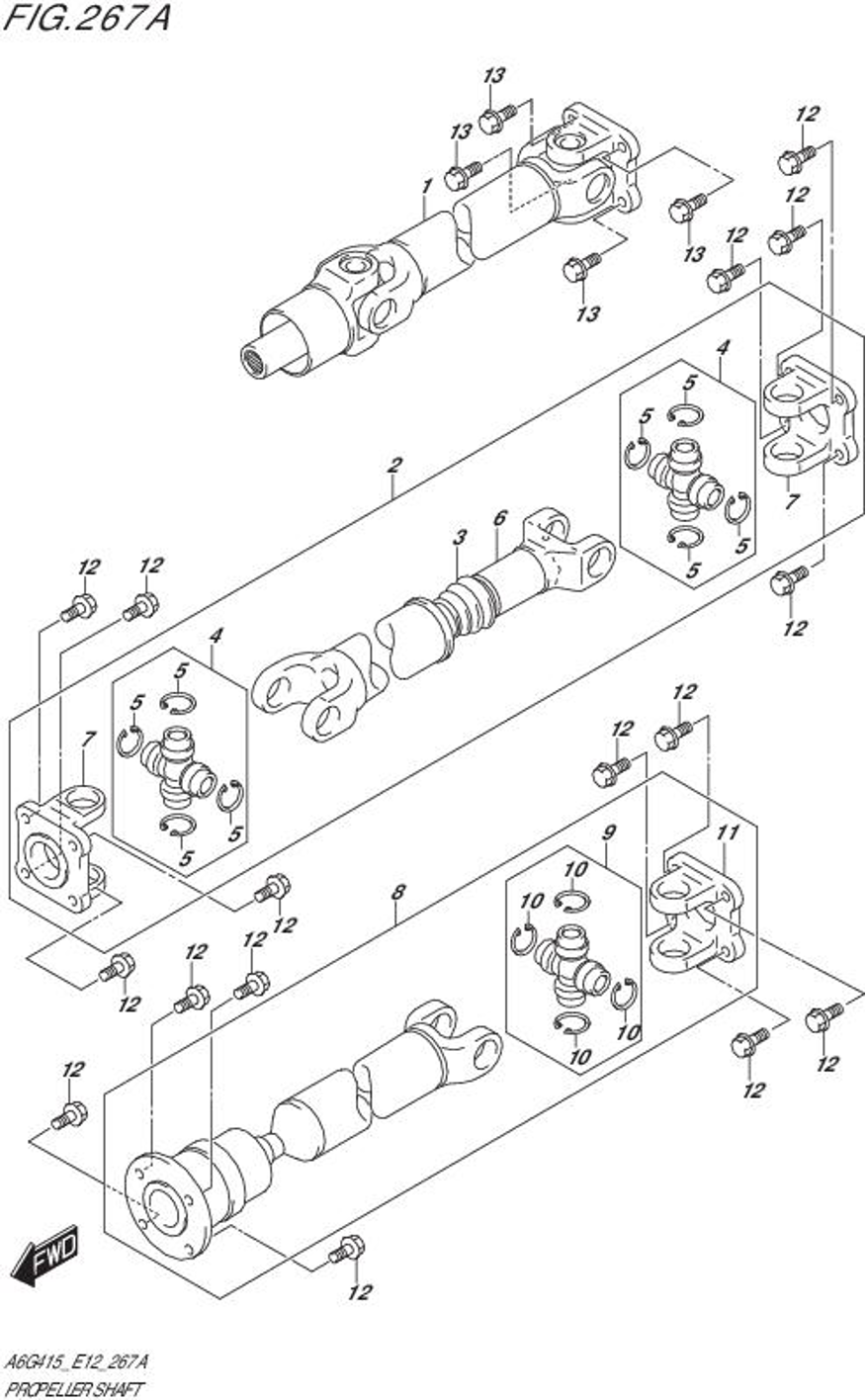

Rear tailshaft CV joint boot splitting/tearing

This one seems to increasingly come up with cars I’ve seen on Facebook in the various groups. Not totally sure if it’s a weak boot or if there’s something deeper going on like overextending the driveshaft or similar.

It relates to the boot on the CV joint on the tailshaft tearing and letting the grease out.

This becomes an issue because Suzuki don’t sell a replacement boot, just the entire shaft. At this stage the couple of people who have had this come up don’t think they’ve hit anything to blame it on but that’s been the assessment for a warranty repair. There are boots available aftermarket for the JB43 and the shaft appears the same so that might be the easiest solution, or for repairing the original shaft then taking it to a driveshaft shop is probably the next best solution. Otherwise it’s really down to an aftermarket option to repalce the shaft entirely for one without a vulnerable boot (if available). It is unclear if the shaft is easily disassembled, until I get one in my hands I can only really speculate that there’s some kind of internal circlip holding it together like most CV joints.

Crank and/or cam seal and/or sump gasket leakage

This so far only seems to be some early cars (but includes mine). It may or may not be related to age i.e. none of the newer cars are yet old enough to show this issue. Manifests itself as a bit of an oil weep apparent at the front or back of the engine. Not all engines seem to do this, and it’s not all that common in the discussion groups.

My car did develop leaks from the front crank seal and it was rectified under warranty along with re-sealing the sump as there were signs of minor weepage at the rear of the engine. After a further 6 months, this weepage hadn’t ceased and it involved replacing the rear main seal. All of these were done under warranty when the car was about 4 to 4.5 years old.

(I took the time to have the clutch replaced with a heavy duty clutch at the time the rear main seal was changed. Suzuki were very helpful in accommodating this requirement and didn’t add any cost for labour to the repair they were doing).

2026 update: the more I’ve helped a few people with this, the more common it appears to be with heavy mud/dirt 4wding, presumably from the seal getting dirt in it and allowing oil past. That might have been the case with mine (it didn’t start leaking until about 2 months after I had water well up into the footwell of the car), though mine was warrantied.

This is an example of a car that has had two leaking rear main seals, but both times it was dirt causing the seal not to seal.

Autonomous braking camera malfunctions

This one appears more correlated with hot climates/sunny areas/cars parked outside all of the time. The camera module suffers a failure due to some issue internal to the module or camera.

If this does occur, the dashboard will turn orange, you will get a flashing warning triangle in the upper part of the dash, and you will get the message SYSTEM WARNING around 5 seconds after turning the car on, as it does some internal self checks.

Note that this error is different to the error you get when the car cannot see past the bonnet or the camera is obscured, which will also produce an orange dashboard and display an error. If you scan your autonomous braking module with a scan tool or software like szviewer then you will get an error code relating directly to the camera module.

I cover the error codes and also error and fail safe states in my diagnostics article.

Mine was replaced under warranty when this occurred and the dealership mentioned they had a few cases where this had happened to people, and it occurred after a particularly long and harsh Perth summer.

Manual transmission issues

These seem to fall into two categories:

- Synchro failures (usually 2nd gear, often first manifested as significant crunching when engaging 2nd)

- Internal bearing failures (usually input shaft, but sometimes symptoms better correlate with countershaft bearing failures, and at least one rear output shaft bearing failure).

There’s also more minor reports of issues with water ingress into the remote shifter housing.

It has come to my attention that the remote selector housing (its not part of the gearbox/seperate) for your gear stick is not a sealed unit.

This is worth mentioning for people doing water crossings with snorkels ect, if you don’t seal up the 2 slots and go through some water crossings, water and debris can enter the housing, and eventually corrode the internals, destroying the bearings in there that sit in a sleeve and support the output rod, and siezing up the selector. (From this post)

Finally, more of a minor thing, but people report difficult selecting reverse (and sometimes first) when stopped.

I after some advice before I go back to the dealership. I collected a new 2022 manual Jimny today with 1,500 miles on it. The gear change feels tight and notchey and putting it into reverse is not smooth and has taken two or three attempts on a few tries. (From this comment thread)

Hey guys just bought a new Jimny (manual trans) and occasionally it won’t go into reverse have to go into neutral clutch out then try again and it will go in fine. (From this comment thread)

Hey guys, got my baby a month ago and just curious if anyone else has had issues with the manual gearstick going into reverse? it’s like it gets stuck half way in and a few people who have driven my car have the same problem. (From this comment thread)

Anyone else finding their manual Jimny can sometimes be difficult getting into reverse gear? Every so often, it just won’t drop in and I have to glide it back to neutral and take two. Or is this just an accepted characteristic? (From this comment thread)

Synchro failures seem to be the most common. While obviously not all are reported on social media, but also people tend to be quite loud about failures especially early in a car’s life, 2nd gear synchro is often mentioned.

[I] lost second gear synchro on mine, which caused damage to the gear which then apparently got into the rear gear as well and damaged that. New gearbox, installed and fluids ended up around $6k and Suzuki refused to say it was a warranty issue when the car was less than 2 years old with nearly 30xxxkms on it. (from this comment thread)

now it’s also crunching into 2nd gear. … I go and pick up the car … Drive toward home, not even 1km down the road and the crunching into gear from 1st to 2nd still there and worse and 3rd to 2nd also (from this comment thread)

I had issues with the gearbox. Gears hard to shift, especially 2, and very dirty oil, with metallic flakes. Suzuki took out warranty and just finished breaking the box…(hammered back). I had to redo it myself to be safe. (from this comment thread)

Internal gearbox bearing failure is less commonly reported out of those with gearbox issues, but still it appears to come up from time to time. Some of these quotes are combined from multiple comment replies to the linked comment thread (and note some are in closed FB groups, apologies, but there’s only so much I can do with those).

Just had the gearbox completely shut itself and they refused to cover it under warranty; mine did the rear output shift bearing; has just hit 100,000 did the clutch at 30,000 but yeah gearboxes shouldn’t collapse bearing that soon; I had upgraded transfer case mounts was their reasoning for it. (from this comment thread)

Has anyone had gear box problems with the [manual] jimny … 2019 75k on the clock and it just dropped 4th on the way to work, won’t go into gear well … Can’t get higher than 3rd clutch is fine … Box making horrible noises when you roll forward in gear … I’ve not done anything crazy with it just been on road driving to work and back for the last 2 years … Can anyone recommend a good workshop? (from this comment thread: appeared to be a countershaft bearing failure)

Just had my gearbox and transfer case replaced under warranty on my 2019 manual with less than 40000km. Metal contaminant found in gearbox oil (was making whirring type noise under load) … wondering if anyone else has had a fault in gearbox/has had to have whole gearbox and/or transfer case replaced (from this comment thread)

Given the amount of people with the cars, and that it doesn’t totally appear to be a km related issue, it’s hard to (presently) say if this is a systematic issue or even what the cause is.

They are (basically) a direct shifting box so notchiness and slow synchros are much more easily felt, plus with a semi direct shifting nature to the linkages you’re at the mercy of that leverage, vs. cables and the linkage leverage of highly remote shifting.

Bearing failures are much harder to explain from that, though issues such as output misalignment from offsetting the transfer case could conceivably cause such an issue. In my experience things like input shaft bearing failures come about from misalignment during assembly: the only common element for those appear to be late 2019 and 2020 cars so it might be something relating to how the gearbox is assembled.

The gearboxes have had one revision, but the only internal part revision is around 5th gear synchro. As the gearbox is a 1:1 gearbox in 5th with the countershaft isolated, it doesn’t really relate to any of the reported issues. The revisions mostly are around discontinued parts which usually is down to a change in supplier.

Rev hang / limp home mode / CAN communication issues with throttle controllers fitted

Throttle controllers are one of the most contentious issues in the ol’ Facey group arguments. On one hand people swear that they magically help the car be more responsive, potentially improve fuel economy and help on-road performance. Others maintain that since they only change the relationship between throttle pedal position and what the car thinks you’ve asked for, they are no different to pushing the throttle more or less hard.

Ultimately because of how they operate and lie to the car about the throttle pedal physical position, they can introduce issues. If you are seeing one or more of the following issues having fitted a throttle controller:

- Random check engine lights

- Rev hang on changing gears/car revving when not touching throttle pedal

- Throttle ‘surging’

- Car going into limp home mode and giving you almost no throttle response

- Dash warnings such as disabling autonomous braking

then consider turning the car off for 15 minutes, unplugging the throttle controller and seeing if that helps. Although many people maintain there are no issues for them with throttle controllers, there are enough people reporting these symptoms to say that they are not foolproof devices with no likely drawback.

Cosmetic / interior / electrical issues

“What’s this black plastic cover on the floor?”

Almost everyone at some point with a Jimny asks about a black, sort of squarish plastic cover, usually found on the passengers footwell or under the seat that’s just loose and flopping around. Well, that’s actually a cover that goes over the wiring to the seat airbag and passenger detection stuff. A lot of people discard them and there is no issue with doing so, although it leaves the wiring connectors exposed under the seat. This risks potentially damaging them or at least unplugging them, making the car think something’s wrong with the seat airbag system.

I’ve had mine out of my car since 2019 and zero dramas, though.

Flaking/thin paint

This more seems to have come about for cars produced post-covid, and is most apparent on cars with multi-stage metallic paint and/or black roofs. The paint is quite thin, meaning it chips easily, and some people report images of flaking paint especially on painted roofs.

Not something I have experience with first hand, and it does seem to come up infrequently as opposed to being a batch of a particular year or month of cars. It’s unclear if it’s correlated to more driving where more stone chips happen, which then manifests itself as peeling paint, or unrelated to this.

MY2022 GLX: 9″ head unit issues

Microprocessor supply chain issues meant that Suzuki in Australia discontinued the use of the 7″ Bosch sourced navigation and infotainment system for a 9″ display unit, based on Android, which does not have inbuilt navigation but does retain Android Auto and Apple Carplay functionality.

Some lucky people have no issues, but many owners seem to report issues such as

- Poor sound quality on hand free for the phone

- Intermittent working of the unit

- Intermittent working of the reverse camera

- Buggy interface to the unit

Some of these units have been replaced by dealers, and some have had firmware updates. This has sometimes resolved it but they appear to be hit and miss. The best solution for this headunit is chucking it in the bin. Some dealers have been better than others at proactive warranty work with replacing the units, but, they are kinda garbage.

Other headunit issues

While the 9″ headunits in MY2022 cars are the most problematic, it isn’t like the 7″ Bosch head units in other 3 door GLX vehicles are without issues. Their main issues relate to:

- Unable to stop the car reverting to the radio on startup

- Reluctance to recognise smartphones via USB

- Slow charging of smartphones via USB

- Little to no mapping support

(and from the middle of 2024, no SD card for navigation supplied, and potentially no navigation software installed)

The radio one is super, super annoying. If you’ve been cranking music on your smartphone, when you start the car it will take time to be detected. In the meantime the car switches back to radio and there’s no way to force it to be off or muted on the radio. I have tuned my radio to a dead frequency as I can almost deal with static better than loud commercial FM voices, but it’s pretty damned annoying. Some very early units appeared to have an aux input, you could have that selected before plugging in your phone & then it would switch to that input but this doesn’t appear to be a thing after about March 2019 vehicles (so presumably a software revision thing).

Not detected a smartphone is a bit different to the issues with the MY2022 head units. Because the Bosch head unit is a little slow processor-wise, if you plug in a phone while it’s still initialising things then it can fail to detect the connection. I wait until the headunit is fully powered right up and navigation is available (as opposed to saying it is initialised) before plugging in my phone.

Another related issue is that wired connections may end up being unhappy if you’re also connected via bluetooth to the car. If you mostly or always want to use a wired connection then do not ever pair the phone to the car via bluetooth. If you have, delete the profile and see if that helps your connection issues.

Slow charging is very difficult to solve. Charge speeds are negotiated via annoying protocols on USB (especially USB-A as per the Jimny’s factory port). An upgraded head unit and changing to a USB-C connector might help but that’s quite involved. No real solution other than maybe consider if you can also use a wireless charging solution to add extra power while it’s plugged in via a wired connection. The alternative would be a wireless CarPlay/Android Auto adapter. I have no suggestions here but they do exist. If you go for this then you can charge using a fast wired charger and still have the phone connected (albeit wirelessly).

Mapping support is the final argument. Only a few Australian mapping updates appear to have been pushed out since the car was released, and they can be expensive. Some people have been charged ~$400 through the dealership for an official SD card, however, the mapping is outsourced to Here Navigation. You can purchase an upgrade for ~$159 (mid 2024 pricing) direct from the mapping developer.

Middle MY2024 GLX vehicles in Australia are no longer supplied with an SD card. This means that the car shows ‘MEDIA’ instead of ‘NAVIGATION’ in the bottom left corner. At least one person has reported that upon plugging in an appropriate SD card with navigation data on it the navigation is still available, but I haven’t yet directly tested this. I’ve also been informed by at least one person that they aren’t shipped with ‘navigation software’ but I’m not sure they actually tested it.

In 2024 the best navigation options are phone based with infinite updates rather than using built in clunky navigation software, but it does depend on having a suitable smartphone to use for navigation purposes and I get that not everyone wants to do it this way.

Evidence of foam breaking off underneath seats

This one is mostly supported through a couple of random comments about finding white foam underneath the front seats, especially the driver’s seat, and there are some posts supporting a ‘fix’ at least in the UK.

It’s unclear, as it seems a bit sporadic, as to how much of this is the tendency of people to get into a 4wd by sliding over the side bolster versus getting up and into the seat or how much of this issue is down to some flaw in the seat foam design rubbing it against the seat frame.

Rear luggage box breaking at the hinges

Another semi sporadic issue that not many people talk about, but times I have mentioned it you get a few people out of the woodwork saying “oh, that happened to mine too”. The plastic supporting the hinges for the rear luggage box is quite thin and sometimes this means it breaks, even if the luggage box is rarely used. It might relate to the way this area is stressed by the parts that go onto the rear seats when they are folded or brought back upright, or it might just be a weakness in the luggage box.

Red mudflaps on Heritage JB74s fading

This only seems to apply to the 300 JB74 Heritage models, and not the 500 JC74/XL Heritage models. Back in 2023 it was noted by a few owners that their red mudflaps were fading. While I don’t have a copy of the dealer bulletin, a Suzuki salesman provided a copy as a comment to one post about these fading mudflaps:

We have recently been informed of a manufacturing fault in the red mud flaps fitted to the 300 Jimny Heritage units. The manufacturer has confirmed that the red material may be subject to fading over time.

In line with Suzuki Australia’s promise to provide the highest level of quality products to our customers, we have sourced replacement mud flaps which will be sent to your respective dealerships within the next 3-4 weeks.

Some dealers subsequently have forgotten about this bulletin, so it is worth reminding them.