Solving death wobbles

Got a wobble at speed in your Jimny? You’re not alone: it’s partly the live axle life, and it is fixable. The problem is people immediately jump to one cause (almost always blaming kingpins) but you need to really diagnose it to actually fix it. Annoyingly, it can be a combination of issues all adding up so you potentially need to do a few things to work through it.

Sections

- Introduction

- Initial assessment/fault finding

- Resolving issues

- Wheel balance

- Tyre wear

- Insufficiently centered wheels

- Loose bolts

- Suspension geometry

- Worn out shock absorbers

- Worn out suspension bushes

- Kingpin preload

- Kingpin/kingpin bearing replacement

- Steering box adjustment/replacement

- Front wheel bearings

- Concluding remarks

Introduction

A really common thing with Jimnys are people complaining about the car wobbling. This happens especially as cars age, but also with people with suspension lifts newly installed, or having put bigger/wider/heavier wheels and tyres on for more offroad performance.

The first thing to realise is there are different modes of wobbling. It could be violent oscillation of the steering wheel which just continue to amplify and ends up shaking the car around a couple of times a second. It could be some shaking that comes in gradually as you speed up, but then calms down for a bit before returning. People also talk about wobbling on the highway as the car is moving around in the wind.

These are not the same wobbles, and they do not have the same causes. Therefore their solutions are also not the same.

We’ll start with the highway wobbles of the car moving around. Fundamentally the Jimny has to run soft suspension and it is relatively brick shaped. The standard shock absorbers are both built to a price and a purpose, and they bias a bit towards flex offroad than on-road comfort. This translates to the car being pushed over and developing a lean when hitting wind. That isn’t neccessarily a problem, it’s just noticeable in a car with soft suspension and relatively light weight and a high centre of gravity.

As the Jimny has some bump steer inherent in its suspension design, this also means the wind moves the car around in the lane a bit. Where you hit a problem with it is that people’s reaction times are often slower than the changes in the wind, especially once you have interractions with other cars or stuff on the roadside verge (e.g. trees, or bridge pylons or whatever). People correct the car but the wind might already have eased off, so the car ends up moving around more than it would if you just left it alone.

If you feel the car is wobbling in this manner then suspension improvements can be beneficial. These can be as simple as upgrading the shock absorbers for better ones: you don’t have to install a full lift kit to upgrade the suspension. It can also be some improvements to the car already: people often run too much tyre pressure in Jimnys, so reset the tyres to factory pressures. You can also improve your reactions and actually do less correction on the car on the highway in the wind, and it’ll actually wobble less. It’ll lean but then slowly come back as the wind eases off. It would take kilometers of travel to actually blow you out of your lane: relax the grip on the steering wheel and just apply minimal course corrections a lot slower than your survival instincts make you think you need to.

If we’re talking wobbles that slowly get worse as you speed up, but then at higher speeds ease back a bit and then back up again, then they are likely the result of something to do with the wheels. Wheel speed wobbles are caused things such as tyre wear, tyre/wheel balance or even the wheel not being fitted to the hubs on centre. Jimnys are barely hubcentric on the front and aren’t at all on the back, and once you go to some aftermarket wheels then the centre bores are larger than the Jimny’s hubs anyway. These kind of wobbles can also be the result of resonance in the suspension, often from too weak shock absorbers with heavy tyres/wheels. As shock absorbers lose their damping abilities, the weight of a wheel and slight imbalances with it can result in harmonics being induced at particular speeds and the wobble is, in essence, the suspension moving up and down. In extreme cases this will manifest as patchy wear on the tyre.

Wobbles that are instigated by slowing down with a small amount of braking, or braking wobbles, may be the result of warped brake discs or brake material buildup on the discs. This may, however, not be the ultimate cause and it could actually be the result of some other issue such as insufficient caster or worn out kingpins; it’s just that the braking provides the biggest input to initiate a wobble.

The final wobbles, which I will term death wobbles, are wobbles that start at a particular speed and just continue to get worse as you go faster. These are quite often the result of something in the entire array of steering components being worn out or otherwise problematic, but it is not as simple as the default cry of many of kingpins. It can also be from worn out bushes, or loose bolts, or also weak/worn out/leaking shock absorbers. Steering geometry also comes into it, as do things like tyre wear. Severe wheel balance issues might be something that only start at a particular speed, but they never ease off so they can be hard to differentiate from wobbles as the result of worn components.

As you can see, there’s both a variety of wobbles and a variety of causes; therefore, there’s a variety of fixes involved. There’s no one perfect fault-finding chart to go through but below we’ll walk through some of the things to check and how you might fix particular problems.

Initial assessment/fault finding

What’s been recently changed on the car?

If the wobbles have started suddenly then the first thing to do is work backwards from the most recent change made to the car. If you just put on different wheels/tyres then start there; if you just installed new suspension then carefully look at the suspension.

I know this seems obvious to the rational thinker but when your car starts acting strangely all of a sudden then rational thinking often goes out the window.

Rule out tyre pressure, wheel balance/centering or tyre wear issues

The absolute first thing I rule out with any car that’s wobbling at anything other than the slow highway wobbles in the wind is to look at tyre pressures, wheel balance or tyre wear issues.

Tyre pressure: set to factory pressures of 26 psi all around. Yes, even if you have larger wheels and tyres (potentially they need to go lower than stock pressures, not higher…). This isn’t the writeup to debate Jimny pressures, but it is something to look at as weird pressure things can cause issues.

Wheel balance/tyre wear issues: you can rule this out by rotating tyres. Wobbles are much more set off by front wheels than rear wheels. Rotating the fronts to the back and the backs to the front and seeing if that changes things is a really good way to check this. It doesn’t take long, even using the factory jack, and helps you rule out issues.

If you’ve recently gone 4wding and you suddenly notice wobbles then a big thing that can happen is either:

- Mud/dirt caught on the tyres, changing the wheel balance

- Losing a wheel weight

Loss of a wheel weight can often by spotted by an area of the wheel that looks less dirty, often in the rectangular shape of a stick-on wheel weight or the wheel weights hammered onto the rim of a wheel for steel wheels. Getting the wheels balanced will fix that right up.

Obviously, if you have dirt on your wheels affecting the balance then wash the wheels and hubs thoroughly to remove all mud and dirt and then try again: is the wobble better now?

The final thing to talk about here is wheel centering. Jimnys do not have the most hubcentric arrangement like many cars people will be familiar with. It’s very possible to fit wheels to a Jimny which are not centred. You have to use the wheel nuts themselves to centre the wheels onto the lugs, see my writeup here for how you do this. This is especially a problem with steel wheels: people will take new ones and just attach them, and basically deform the wheels so the wheel nut holes are no longer centric with the wheels. You’ll never get them to balance once you do this, so, be careful with fitting new steel wheels. If you’ve bought used ones then be a bit suspect of how they’ve been fitted and do your best to work them on centre using the wheel nuts slowly. With all steel wheels it’s also important continually keep torquing the wheel nuts to factory spec as you drive on new wheels as they can loosen up and that will also stop them being centred.

Related to this is that Jimnys can benefit from being fingerplate balanced, i.e. balanced with reference to the lug nut holes and not the centre bore like most wheel balancing machines use. Not all places will do this kind of balancing; for hard to balance all terrain or mud terrain tyres it can be beneficial to find somewhere prepared to do fingerplate balancing for you.

Suspension health check

Next on the list of “stuff to check” is suspension health check. To really diagnose this you’ll want to jack up your car and support it, and use a long lever and some spanners but even just a check around can help.

Visually, look for any leaking shock absorbers or other signs of things being a bit untoward. Obvious oil leaking out of the shock is one sign; dust that’s hanging around just on one shock is another sign of a less obvious oil weep. You can also bounce the suspension and if it noticeably bounces repeatedly then that’s another good sign of a worn out shock absorber. All of those things will reduce shock performance, amplify issues and can well cause wobbles.

The next health check is to look for obviously loose bolts and those less obviously loose. Missing nuts or bolts that can move around are a really good sign of really loose things, but in an ideal world you really need to go through and make sure everything is tight to factory specifications. Bolts becoming loose over time have become the subject of Jimny recalls before (albeit for generation 3 Jimnys). Just one loose panhard rod bolt, in that recall’s case, can cause steering wheel wobbles as mentioned by the recall notice.

Once everything is confirmed (not assumed!) tight then you can go onto checking suspension bushes for wear. Obviously torn or cracked or collapsed bushes can cause issues, but use a long lever like a prybar and verify that the bushes don’t excessively move. Bushes, being rubber, will move a bit but they should be still quite solid feeling. If they aren’t then they’re very good candidates for causing wobbles as things can move around.

The other part to really concentrate on when it comes to death wobbles are the 4 ball joints that are part of the steering assembly. Check the drag link to steering box, the drag link to passengers side wheel, and both ends of the toe rod between the two front wheels. Any play in any of those will result in the wheel wobbling around and carrying on.

Steering wheel play

Another often overlooked component when it comes to death wobbles is the amount of steering play. The Jimny, using a steering box, requires a certain amount of play in the steering otherwise it will bind up at the ends of its travel (where there’s less wear than in the middle). The official specification is there can be up to 30 mm of movement of the outside of the steering wheel in terms of play. Certainly there should be some play, but if you’re approaching the 30 mm mark then it is worthwhile looking at why.

There’s a few components to check: check the amount of play in the steering column universal joints down to the steering box first. These are best checked by having someone else wobble the steering wheel when parked (but with the ignition on, so the steering lock isn’t engaged) and you look at the engine bay and see how much of the steering wheel movement is transmitted down to the steering box. Assuming that’s ok then there is adjustment on the steering box itself, although getting this adjusted right can take some feel and experience, unless you feel like properly measuring the internal friction via initial torque to start moving the steering to set the backlash.

If your steering box is worn excessively then adjustment will mean it will absolutely bind up at the ends, and at that point you need to find a new steering box. While the steering box is made by Koyo, it is only made for Suzuki and overhaul kits do not seem available. As the cars age there might be reconditioning/remanufacturing services but at present I’m not aware of one.

Wheel alignment

Another component that can introduce wobbles is the wheel alignment. Recall from my suspension glossary article that very little of the Jimny’s alignment parameters are adjustable? Well, one area of adjustment is toe and if you have toe out (as opposed to toe in) then the car can wobble back and forth like a shopping cart. A lot of alignment shops set the Jimny up for zero toe; they are meant to run 4 mm +/- 2 mm toe in, so having them right on the edge of zero toe can reduce stability and introduce some wobbles.

Wheel alignments for Jimnys often are overthought: they can’t get a 4 wheel alignment, so paying for a fancy one isn’t necessarily worth it, but getting alignment parameters through a wheel alignment can be a good cross-check on what’s happening. Other than the toe:

- Excess camber front or rear can indicate bent axle housings which will introduce all kinds of weirdness

- Weird kingpin inclination (KPI) angles/out of spec KPI angles or even KPI angles that change when they check them again can be a sign of insufficient kingpin preload or worn out kingpin bearings

- Rear toe can also indicate worn out rear wheel bearings, or bent housings as well

These are all good things to know as you’re diagnosing a wobble: the price of an alignment could find issues that end up saving you more than just fully loading up the parts cannon to sort it all out.

Checking kingpins

And only now do we get to the thing that most people blame. While they are responsible for a reasonable number of death wobble style wobbles that people report, they absolutely universally aren’t & it’s good to work up the hierarchy of things to solve first.

Other than checking with a wheel alignment, you can look to see if there’s noticeable play in the swivel hub itself. If you can lift it up or down and move it around on the kingpins then they absolutely are worn out and are lacking in preload. Crunchy steering can also be the result of worn out kingpin bearings.

The other check you can do is actually remove a kingpin (just do one at a time) and check what they’re doing. This is doable at home:

- Jack the car up and support the axle

- Remove the wheel and brake assembly (makes it easier to access)

- Mark the kingpin (either top or bottom) so you can reassamble it in the same orientation

- Undo the 4 bolts and remove the kingpin carefully, and make sure no dirt will fall into the hub while the kingpin is removed

- Check kingpin for any obvious signs of wear or where the bearing has been rubbing. Also look for corrosion or unhappiness in the bearing down in the swivel hub

- To reinstall kingpin then use sealant around the base of the kingpin and place it back into the swivel hub in the same orientation/position where it was before you started this process

This will hopefully help rule out needing to properly overhaul the swivel hubs. It is possible to just ‘shim’ a kingpin to add bearing preload which can be a temporary fix, but in my experience with gen4 Jimnys they have sufficient factory preload when the bearings aren’t worn out. It isn’t needed unless you want a temporary fix to get you a bit further down the road. Gen3 Jimnys did have issues with insufficient kingpin preload and this is also a current issue with 5 door Jimnys due to insufficient kingpin length. Revised kingpins are available for 5 doors and worth swapping in if you have wobbles, though in theory it’s a warranty item.

Resolving issues

Now you’ve gone through and thoroughly diagnosed what’s up with your car, here’s a few insights into resolving those issues. Again as per the diagnosis flow this sort of works through the hierarchy of cost/difficulty.

Tyre wear

This one is the absolute easiest to resolve: rotate the tyres and make sure you don’t have something going on like incorrect pressures so you’re wearing just the edges or ballooning out the tyre. If the tyres are hugely worn weirdly then it can be worth changing them. While 4wd tyres have a lot of tread depth, you will get maximum performance in the initial wear rather than as they are more deeply worn. You definitely lose offroad performance in the bottom half of the tread once it is shallower than a new tyre.

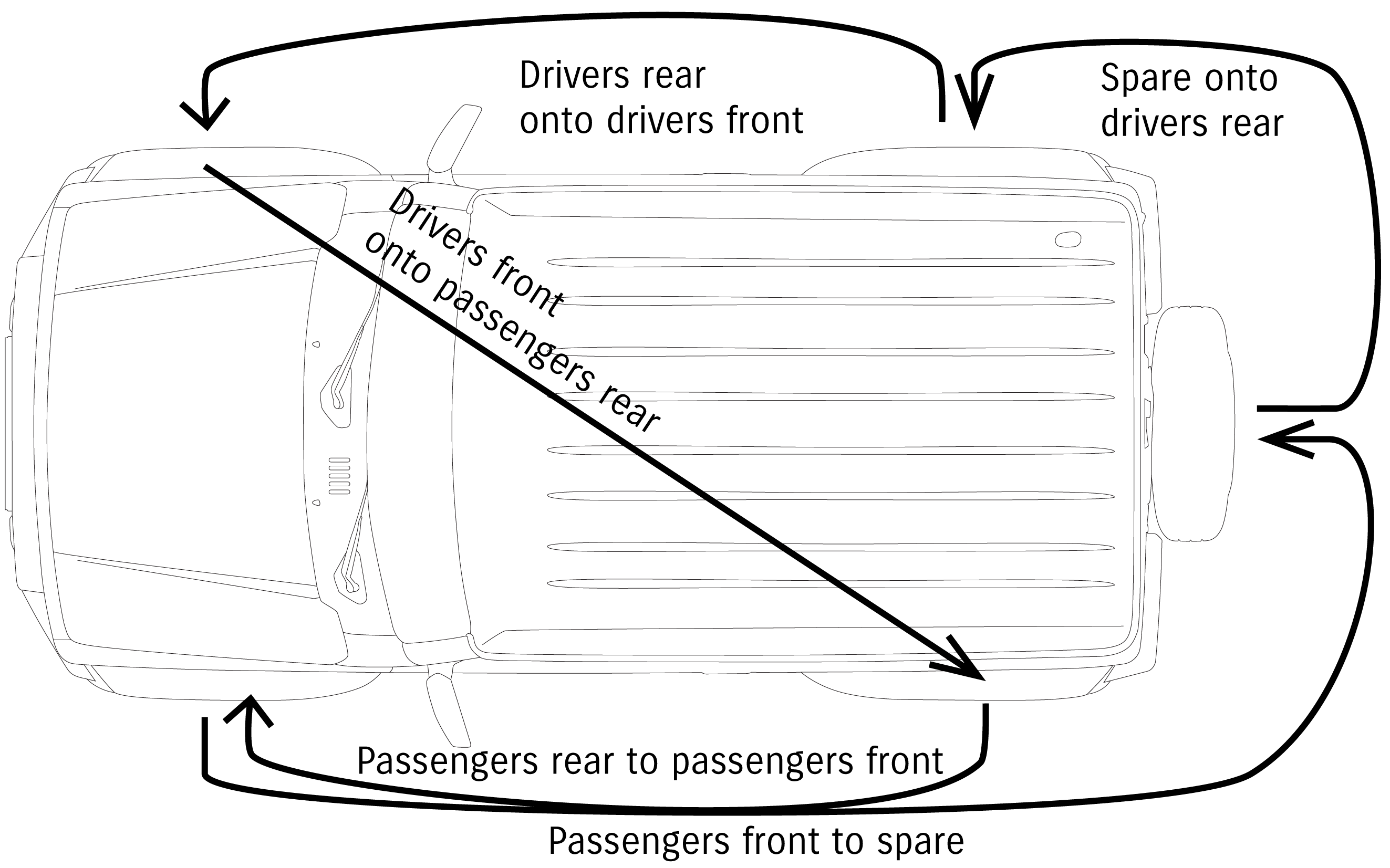

You should definitely do a full 5 tyre rotation here, but if you don’t want to use the spare then just rotate front to back and back to front. It can be useful to swap sides every second rotation too, mostly so you aren’t putting the same tyre back on the front next rotation.

Scalloped tyres with noticeable feathering can be a sign of wearing out shock absorbers, or, shock absorbers that have damping characteristics that don’t match how you are driving the car. It can be beneficial in these cases to consider changing to a different set of shock absorbers: if it’s just loss of shock performance then stick to the same brand/type if you’re happy with them. If, on the other hand, it’s down to the shock characteristics then it’s time to consider trying some other shocks.

Insufficiently centred wheels

This is another one that’s mostly simple to solve: when you do the tyre rotation, take your time to carefully align the wheels to keep them on centre.

If you have aftermarket steel wheels and you just absolutely cannot get them on centre then you might be dealing with wheel nut holes that have been pushed off centre by incorrect fitting or them working loose over time and wobbling around. In this case unfortunately the solution are replacement wheels (and taking your time to centre those new ones when you put them on).

Wheel balance

Solution here is also really simple: get the wheels balanced again. Nearly anywhere you take the wheels to do it will do a dynamic balance, but some shops do it better than others. In addition, if possible get it balanced via a fingerplate adapter to balance it with reference to the wheel nut holes rather than the centre bore; this will rule out any loss of concentricity in the wheels and match how the wheels are installed on the car.

Suspension geometry

If one aspect to your wobble is suspension geometry a bit weird, then time to rectify that. Got a lift installed and it’s a bit nervous on the highway, or you had an alignment done and the caster is basically 0 or negative? Time to install some form of caster correction and fix this up. Toe a bit weird on the car? Get it aligned for a little bit of toe in and it’ll be much happier and not flapping around.

If other alignment things are a bit weird then you really need to rectify what’s going on with that, e.g. it might be you really do have a bent axle housing or similar and you need to solve that. Since camber or rear toe isn’t adjustable at all, if you have anything appreciable going on here then time to get in and replace the bent bits and the car will drive significantly better.

Loose bolts

It seems obvious but if you have any loose bolts then obviously tighten them up to factory torque settings. Where this can get more insidious is where components aren’t totally right and things are holding bolts off from being tight. An example might be a poor choice of radius arm mount protectors, or, incorrectly sized replacement panhards where the centre bore of their end bushes is different to the bolt size. In these cases even properly tight will not be holding things where they need to be and will cause wobbles. In these cases then you need to replace components or work out what’s stopping something getting tight (e.g. is the bolt’s shoulder too long for the radius arm protector to properly tighten?) and fix that root issue.

Loose suspension components

Just like loose bolts then this is a case of getting in and replacing those components. The toe rod ends (tie rod ends for most people, but technically not correct) are a really common place for wear to cause wobbles. They aren’t necessarily hard to replace but a) obviously get a wheel alignment done after and b) make sure the jam nuts are done up nice and tight so they don’t flog themselves and self-delete their threads. The end of the draglink connecting up to the steering box can be a real pain to release and is more expensive than the regular toe rod ends, so also consider if you want to tackle this or pay someone to do it.

Worn out shock absorbers

I’m reiterating this as it’s own thing for you to go check for leaking shock absorbers, or check the bounce on the shocks. The way a partially worn out shock absorber can amplify slight wheel imbalances that would otherwise not be noticed is a huge part in a lot more wobbles than people might realise. I’ve even experienced this (albeit in other cars). I chased wobbles for ages, and the only cure was literally unbolting the old shocks and put in new ones.

Worn out suspension bushes

Another one I’m separating out from loose suspension components. Bushes really do need to be checked thoroughly for excessive movement. A lot of mechanics will just sort of pull on the bars and be “yeah, they’re solid” but you need to really look at how much they’re moving when placed under load. There will be some movement from things like panhard rods or radius arms, but it shouldn’t be a lot. You should also be able to see the movement as being gradual and getting harder the more you push on an arm. The other thing is that you will see cracks develop in near new factory bushes (especially radius arm bushes); the issue arises when there are significant number of cracks and the bush can move a lot quite quickly and then spring back with almost no resistance. It’s that, rather than allowing gradual movement in either direction, which produces wobbles.

Kingpin preload

Initial caveat: if you have a 5 door Jimny then this might be your issue. 5 door kingpins are different to 3 doors (and indeed they run a different sized bearing) and initial batches had kingpins machined a bit too short. Thus the cars develop wobble pretty quickly as the kingpin bearings settle in and wear a bit as they lose preload. While it’s not subject to a recall, they are (generally) being replaced with a revised part number under warranty. Some people with modified cars might get more pushback on the fix, but it is doable DIY relatively cheaply if you get knocked back: you just buy the revised kingpin part and replace it one by one. Don’t even need the rebuild the swivel hub fully to fix it.

Now we get to the thing that most people jump on as a solution. “Yeah, I had wobbles, I had the kingpins shimmed and it’s all good”. It’s important to understand what this fix entails but also why it might not always be the best solution for your problem.

In part this arises from the generation 3 Jimnys which did suffer from lack of kingpin preload. This was subject to a service bulletin from Suzuki as per that last link; it became the hammer that everyone used to drive in the nail of ‘oh, I have steering wobbles, better shim the kingpins’. This also lead to a rise in aftermarket adjustable kingpins to dial in the preload on the kingpins. As machined, generation 4 Jimny kingpins (at least for 3 doors) provide more preload than generation 3 kingpins. Thus if everything is healthy and happy then the car will have sufficient kingpin preload and shouldn’t need shimming.

Shimming can be a solution to semi to nearly worn out kingpins/kingpin bearings to buy you a bit more time, but it is a bandaid fix in this case and not an ultimate solution.

It’s important to understand the drawbacks of this, too. Kingpin bearings are conical roller bearings, and so the harder you ‘jam’ them into their races the more drag they will experience and therefore the more wear. It’ll stop things wobbling around but at the expense of a) heavier steering and b) more bearing wear as you steer. Eventually you’ll wear groves into the races in the axle housing and then the steering will become incredibly ‘sticky’ and the wobbles will get worse. More preload in that case will not fix the problem but just jam the steering up more.

There is a steering force limit: 59 Nm as measured at the rim of the steering wheel. You shouldn’t need more than this force with the car stationary but engine running and the tyres at correct pressure to turn the steering wheel. If you do then you probably have too high kingpin preload and you need to look at some other kind of solution.

Shims are available in a range of thicknesses to add preload to the kingpins. I’d suggest sticking with about 0.1 mm top and bottom as a start to see if you can cure wobbles temporarily with this approach. However, you can go more so long as you don’t exceed that steering force number. Shimming itself is easy: take off the wheel and brake; undo an upper or a lower kingpin, add shim to the post and new sealant to the kingpin; refit kingpin and repeat with the other kingpin on that side of the car which you hadn’t yet done.

When you’re inspecting the kingpins, if they are significantly worn on the posts then that can be from lack of preload, but also can be significant enough that you need to replace them. If they’re worn and the bearing can move around on them, even just the tiniest amount, then that translates to a lot of movement at the wheel and therefore a lot of wobbles.

Kingpin/kingpin bearing replacement

Once you’ve ruled out shimming as a solution, or you prefer to replace the kingpins then you need to source new kingpins and new bearings and replace them. This is already covered by me in my swivel hub rebuild article I’ve written up, since you need to strip the swivel hub down to get the races out of the axle housing and replace everything.

It’s quite straightforwards and takes a bit over an hour per side to strip the side down and put it back together. Allocate more time if you’re going to do stuff like paint the swivel hub so it looks nicer.

Steering box adjustment/replacement

I haven’t written this up yet, but it’s also possible to adjust the steering box. The problem with doing this is people often overly tighten the steering box which is capital-b BAD. Especially as the box wears, you’ll get more wear in the middle than the ends and you need to set the steering box up so it will not bind up anywhere in its travel, even as it warms up through use and repeated steering.

There is an adjuster on top of the steering box (a slotted head bolt) with a locknut stopping it. This locknut is relatively tight (37 Nm tightening torque) and also requires sealant underneath to stop any potential leaking of oil from the box. You undo the locknut fully, clean off sealant from the bolt/screw threads and the nut itself, tighten the screw up slightly to take up some more of the slack, add some sealant to the thread and base of the locknut and refit it; torque the nut to 37 Nm while holding the adjuster screw in place.

There is a specification to check that you haven’t overly tightened the steering box and that is that the ‘initial’ torque to move the steering box with all steering linkages removed is 0.45 to 0.85 Nm. Less than that and the adjuster needs to be tightened, more than that and it needs loosening. Note that you measure this at the input to the steering gearbox and you need to have all linkages removed for testing.

The steering box is worn out when the adjuster screw’s slot is lower than the locknut’s upper face when the adjuster is correctly tightened. I’ve never seen a steering box get that bad and still be driveable, though.

Front wheel bearings

This is the final possible cause but it’s relatively unlikely and more noticeable as other clunks or noise not just slight highway speed wobbles. Replacing it is very simple: strip wheel and brake off and work through to the wheel bearing/spindle removal in my swivel hub rebuild article; press out bearing and put in a new bearing. Note there’s a big circlip retaining the bearing so remove that and the bearing seal before pressing!