Throttle controllers

One of the real arguments in the Jimny world (elsewhere in the car world, too) is around the use of ‘throttle controllers’. I’ve gone and grabbed a throttle controller, plus some data logging equipment, to look into their use and various claims about them.

One thing is I won’t disclose what throttle controller I tested here. For the Jimny’s purposes all throttle controllers on the market connect to the accelerator pedal in the same manner and therefore only have the same abilities to modify what the ECU knows about pedal position. Results I talk about here are therefore generic.

We will step through the following sections:

- Throttle theory

- ‘Throttle controller’ basics

- Bench testing a throttle controller for the Jimny

- Real world demonstration of throttle controller parameters

- Conclusions

I know this is a theory heavy article, and quite dense, but hopefully you will be able to get a greater understanding of how electronic throttles work and what a throttle controller can and can’t do. Let’s bust through the marketing and hopefully work out if it’s something you want for your car or something where you’re better off spending the money elsewhere.

Throttle theory

What is throttling?

There are a number of definitions of a throttle, many of which refer to the control of fuel to an engine; the Oxford definition is “a device controlling the flow of fuel or power to an engine.”. The Macquarie Dictionary in Australia defines it as a device to control the fuel flow to an engine; this isn’t necessarily how most petrol engines are throttled, however, so we’ll run with the Oxford option.

The definition I will work from here is that a throttle is device used to regulate the power output of an engine by controlling parameter(s) that affect the physical flow of air or fuel into an engine, or by changing the timing of combustion events. This is done because no-one, not even the boldest P-plater in a McDonalds carpark, wishes the engine to be at 100% output 100% of the time. This output is reduced by throttling the engine by some means. Although classically it is performed by physically reducing airflow in a petrol engine, it can also be achieved by changing when or if spark events occur to make combustion happen (advancing or retarding the timing, or an ‘ignition cut’) or by how much fuel is injected into the engine.

Classically, a diesel engine is throttled by reduction in fuel flow and a petrol engine is throttled by reduction of airflow. In the case of a petrol engine this is normally achieved by a movable plate that chokes the air coming into the engine. With less air, less fuel is required to be burnt and there is less power produced by the engine. This allows the performance of the engine to be controlled as required.

Physically controlled throttles

This is the example of a throttle plate from a generation 3 Jimny: the bronze coloured part is the throttle plate, and the throttle cable rotates the plate to change the airflow into the engine from almost no airflow at idle to almost full airflow at ‘full throttle’.

When the throttle pedal in the car is depressed, a cable is pulled and this rotates the shaft that the throttle plate is connected to. This, in turn, increases airflow into the engine which is followed by increasing fuel flow controlled either by physical means (in the case of a carburettor or mechanical fuel injection) or electronically (in the case of electronic fuel injection).

When the pedal is completely released, the engine is at minimal airflow and therefore minimum power production; at full throttle the engine is doing its best to give maximum power. Throttling an engine is really that simple: you’re doing something to control between minimum and maximum power that the engine can give. Doing this electronically is how modern electronic throttle systems work.

Drive by wire (electronic throttles)

Definitions I’ll use going forwards

Now we’ve gone through the theory of throttling an engine, both how it used to be done and also how it is done in a world with electronic throttle control, I’ll provide some clear definitions in how I will write this article. One of the biggest problems with ‘throttle controllers’ and people’s understanding of them is a lot of mixed definition. To clear up confusion:

- The pedal you step on to make the engine go faster will be called the accelerator pedal;

- The request you make of the ECU for how much you want to engine to deliver is the torque demand:

0% torque demand means maximum engine braking for that engine speed and 100% torque demand means maximum torque provided by the engine; and, - When I refer to the throttle, I am referring only to the electronic throttle body which is driven by the ECU. Going ‘full throttle’ with the pedal means pushing the accelerator pedal to its maximum position, and ‘coming off the throttle’ with the pedal means the accelerator pedal is at its rest position.

Let’s now turn our attention to the Jimny in particular.

How the Jimny’s drive by wire system works

Direct from Suzuki, the Jimny’s accelerator pedal, ECU (they call it an ECM – engine control module) and throttle body interract in the following way:

ECM detects depressed extent of the accelerator pedal based on the signal voltage of the APP sensor. Using that data and engine operation condition, ECM calculates the optimum throttle valve opening. On the other hand, it detects the throttle valve opening based on the signal voltage of the TP sensor in the electric throttle body assembly and compares this value with the above calculated optimum throttle valve opening. When there is a difference between them, ECM changes the duty ratio (100% to 0%) of throttle actuator control according to this difference to drive the throttle actuator (4) in the electric throttle body assembly. When there is no difference, ECM fixes the duty ratio to about 15% to maintain the throttle valve opening. In this way, the throttle valve is opened and closed to achieve the optimum throttle valve opening.

Suzuki Electronic Throttle Control System Description, © Suzuki Corporation 2019

In this system, TP sensor and APP sensor have 2 sensors (main and sub) each to assure highly accurate and reliable control and abnormality detection. When ECM detects an abnormality in the system, it stops controlling the throttle actuator.

This throttle body is not equipped with IAC valve for idle speed control. Idle speed control is performed by the throttle actuator by adjusting the throttle valve opening.

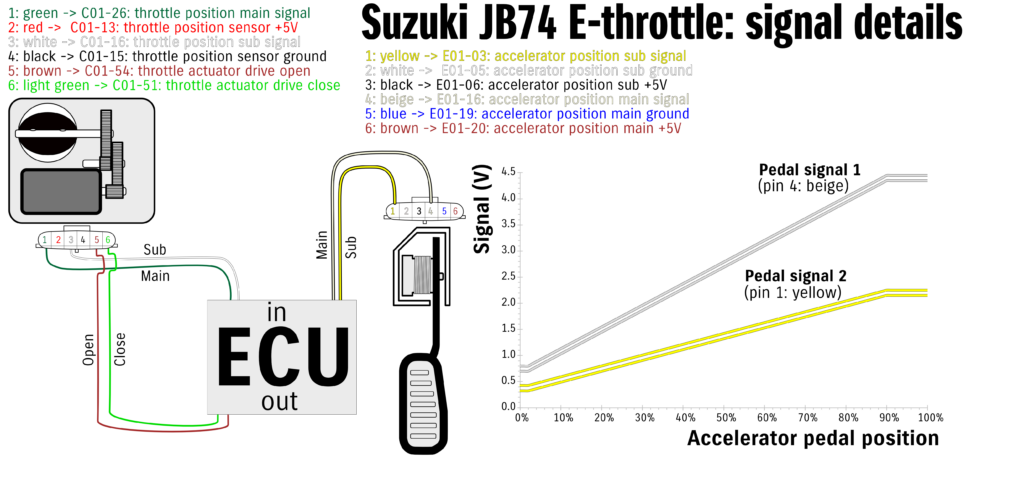

Diagramatically it looks like the following:

A few things come out of this. First off, the ECU only receives the accelerator pedal position sensor as an input. It uses this input to make decisions,but the throttle itself is controlled by the ECU. When you command acceleration using the accelerator pedal, you’re really asking for how much torque you want the car to provide out of what it currently can provide. So, say you’re at 3000 rpm and 0% throttle: you’re asking for 0% of the torque available at 3000 rpm (happens to be ~115 Nm). If you push the pedal to 25% then you are asking for 25% of these 115 Nm (so ~29 Nm). The car will then decide how best to give you that.

The pedal also has some set boundaries:

- 0-2% of pedal position = idle; 0.700 – 0.800 V on main and 0.325 – 0.425 V on sub signal

- ≥ 87% of pedal position = 100% commanded; 4.350 – 4.450 V on main and 2.150 – 2.250 V on sub signal

Voltages received between those end points are interpolated linearly (at least according to all documentation out about the e-throttle system in the Jimny), but that doesn’t mean that there aren’t non-linear mappings within the ECU itself. Further down this page I have documented physical position versus reported throttle % versus main channel voltage.

Ultimately, this is something to realise: the pedal is not connected at all to the throttle, and all you are ever doing on the input side is providing a signal as to how much pedal you have pushed via the 6 wires on the accelerator pedal.

Throttler controllers

We now turn our attention to a throttle controller and how they work. Throttle controllers, in general, sit after the accelerator pedal but before the ECU and they change the mapping between physical pedal position and requested torque values. Some advanced systems will hook into the CAN bus via the OBD2 port, and/or have an independent power source, but many just use the accelerator pedal signal lines.

These throttle controllers do this to provide a different pedal feel. Pedal feel can be an important factor in the perception of a car’s responsiveness, e.g. as Mark Skaife demonstrates in a test of a V8 touring car (discussion starts 4m22s in the video)

What is being referred to in this video is changing the relationship between pedal position and what the engine is being asked to do (note in this example it isn’t a drive by wire system: you can alter the pedal behaviour in mechanical systems, too). Initial responsiveness can be improved by having more % of the throttle commanded early in the throttle travel, or you can dull the throttle response by requesting less % of the throttle early in the throttle travel.

Claims by throttle controller manufacturers or people with them

Throttle controller manufacturers, and people who use them, claim some of the following benefits to their use:

- Increases acceleration

- Reduces throttle lag

- Reduces fuel consumption

- Reduces the ECU’s filtering of accelerator pedal position

- Will not cause check engine lights/ECU faults

Examples of these types of claims by people who’ve installed throttle controllers include:

Some of these really can’t stack up based on how throttle controllers work, at least rationally, so let’s dig into how they work and therefore what they can or can’t do in the Jimny.

Throttle controllers in the Jimny

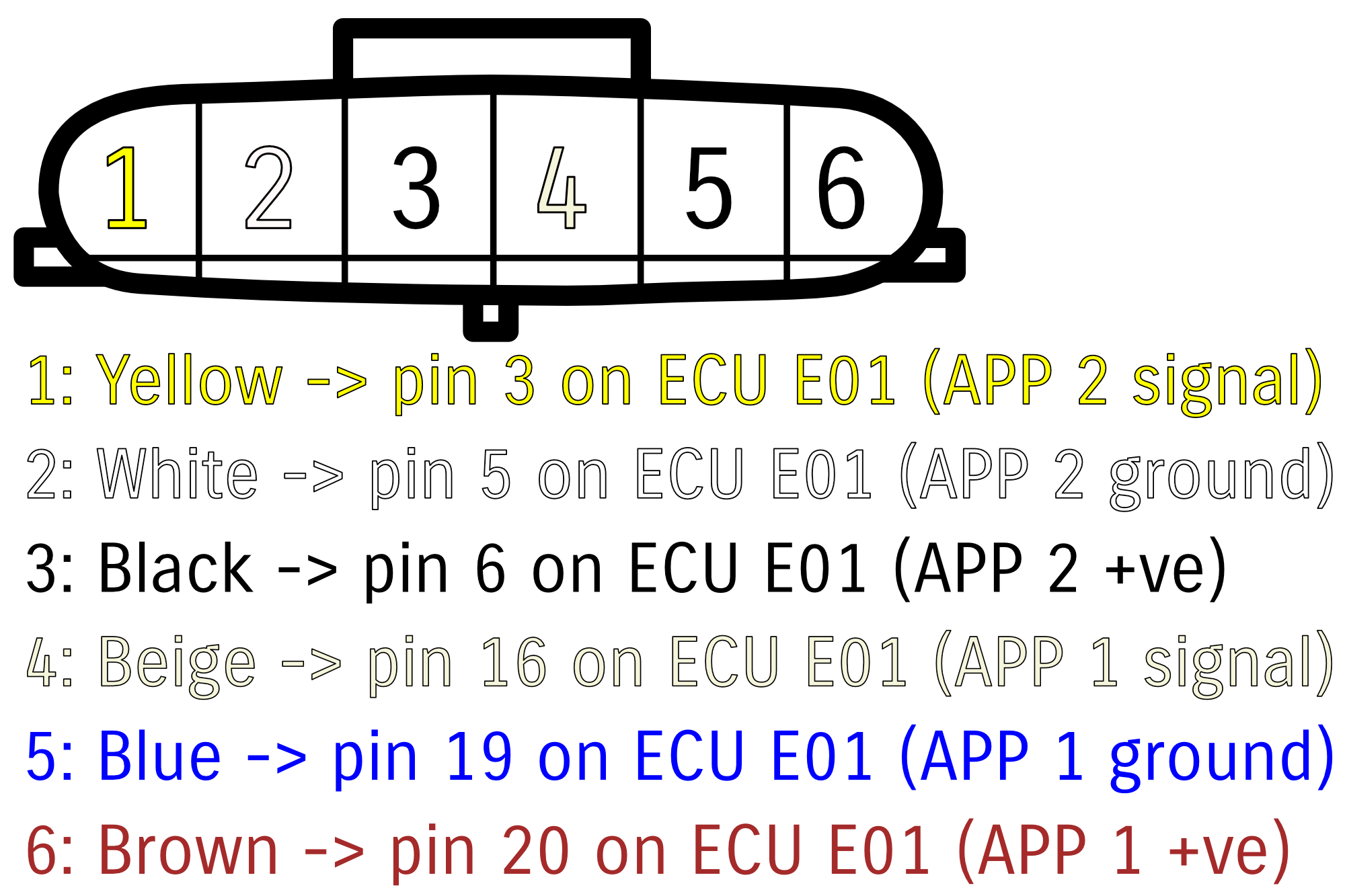

All of the commercially available throttle controllers use just the accelerator pedal plug to plug in. As per the wiring and what I’ve shown above, this gives them access to these 6 wires:

Essentially, there are two independent 5V lines (pins 3 and 6), two pins connected to ground (2 and 5) and 2 pins that provide a signal which is a varying voltage based on the pedal position. There are no CAN lines in this plug, so all that any Jimny throttle controller can do is provide different signals on pins 1 and 4 to provide a different pedal position signal to the ECU. They cannot inject CAN data, since they are just on signal wires to the ECU, and they cannot receive CAN information like vehicle speed or gear position to make different decisions based on different driving states.

The throttle controllers, notably, do not actually go between the ECU and the throttle. That is, they are not controlling the throttle at all. They are simply reporting a different pedal position to the ECU based on their set program.

Just to reiterate: this means they are only ever providing a different INPUT to the ECU, not changing the OUTPUT of the ECU. If they did change the output of the ECU for the physical throttle plate position, and also adjusted what they told the ECU it was doing, then they would be controlling the throttle. Instead of being throttle controllers, they essentially should be called ‘accelerator pedal’ controllers.

Issues you could have with a throttle controller

Proponents of throttle controllers are quick to say “I’ve had one installed for x months and I had no problems”. Ultimately that isn’t the situation for everyone who has installed a throttle controller. A reasonable number of people who pop up in Facebook groups with random check engine lights or odd running cars end up being faults with throttle controllers. Potentially these can be solved as simply as unplugging the controller. Some faults, however, will require clearing either by unplugging the car’s battery for 30+ minutes or in the worst cases a scantool to clear the codes first.

Examples of these problems as reported in the various Jimny groups include the following:

Has anyone had any problems with their jimny revving extremely high in park and sometimes the other gears due to a throttle controller?. I just disconnected mine and the high revving stopped. … only had it in since feb

One month after installing … now experiencing throttle hesitation during acceleration. Happened on a few occasions in [multiple] modes. Have since removed the throttle controller for safety concerns and tried reaching out [to supplier] support but received no response from them. (This one included basically going into limp home mode and allowing zero throttle no matter where the accelerator pedal is pushed to)

having some troubles with the jimny, randomly had a orange collision control image come up and the ebs turned off sign, car went into limp mode than accelerator had a mind of its own for abit. Now orange engine light. Anyone had something similar? (Diagnosis in the comments ended up being a throttle controller issue)

Drove fine yesterday… Now, ESP failure warning, ESC unavailable, feels like it’s really sluggish like it’s gone into limp mode (have a throttle controller normally on full sport setting), 1st to 2nd gear change is clunky.

Ultimately, they are not necessarily risk free as these comments demonstrate. Limp home mode basically gives you zero throttle, so if it falls into that mode when on the highway it can be a significant safety issue.

Since the units get their power from the accelerator pedal signal circuits alone, there can be issues with under volting. Those signal lines are not rated for anything other than the power for testing the pedal position, and so excessive current draw could cause issues with the ECU, since the draw there is competing with other 5V signal lines.

You can also end up with a situation where the ECU does not believe the throttle pedal. Since the accelerator pedal position sensors have redundancy, and a predictable relationship between the two of them for any pedal position, the ECU can also monitor reliability if these signals. If the two signals do not agree within the error range for each of their values then the car will provide particular fault code(s) and disable the throttle. Remember that phrase from earlier from the description of the Jimny’s e-throttle system “When ECM detects an abnormality in the system, it stops controlling the throttle actuator“? Yep, if the throttle controller stuffs something up in the pedal signal, congratulations, worst case you now have zero throttle response.

Real world testing in the Jimny

Since noone believes the ranting of people on the internet (nor should they) I have gone and tested this. As stated in the intro I won’t be mentioning the brand of throttle controller because these findings are more generic than people realise, since they hook in the same way.

Physical pedal position and requested torque demand

Relationship between pedal position and requested torque

Lag between pedal movement and requested torque

Fuel economy

Acceleration

I don’t really feel like I want to thrash my car repeatedly from a standstill, so for this test I accelerated from 20 km/h to 80 km/h (GPS measured) in a 100 km/h zone, using 2nd gear. This equates to starting at ~1360 rpm and up to near 5500 rpm. To time these runs I have both evaluated rpm vs. time from data logs obtained via szviewer and also a video of the rev counter and speedo from a gopro on my steering column. I did 3 runs with the controller off and also with the controller in maximum acceleration mode.

I used full throttle for all runs, which were performed on the same day & immediately after filling the tank of fuel so there won’t be much weight difference between each run.

Qualitative driving ‘feel’ notes

I had my partner put the controller into different modes without showing me what mode they were putting it in, and I drove the car to give my notes on each mode.